|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Optimizing America's Cup Yachts: Andrew Mason January 11, 2011 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

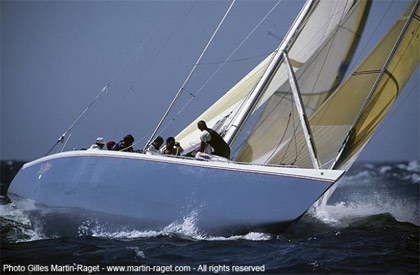

For the 2007 America’s Cup, Andrew Mason created a DNA structure for the ACC yacht class, and then used it to race virtual fleets against each other, automated by computer, culling out the top performers and cross-breeding them until the best of the breed was found. What impact can Genetic Analysis and automated optimization play in designing the new 72-foot catamarans and wingsails for the 2013 America’s Cup? Does Oracle Racing now have an insurmountable advantage on wingsails? Is this advanced study within reach of anyone other than the teams with the most money? Andrew explains his innovative methods in this interview with CupInfo: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For the past twenty-five years, Dr. Andrew Mason has been a prolific contributor to the field of computer-aided design and analysis tools for naval architecture. As the creator of the Maxsurf suite of software, Andrew helped revolutionize the design process of naval architects and yacht designers. Andrew also has made a significant contribution to the America’s Cup, starting with software for both Ben Lexcen and the Kookaburra team for the 1987 America’s Cup in Fremantle. This work led to a long winning streak, commencing in 1992, with the Maxsurf software written by Andrew being used to design every IACC challenger and defender in the America’s Cup match since that date. After the 2000 America's Cup in Auckland, Andrew focused on how the yacht design process could be improved, studying in particular the application of Artificial Intelligence methods to automate the search for the fastest yacht. Beginning with investigations into the estimation and optimization of resistance for fast catamarans, the research culminated with Andrew being invited to work with the Alinghi syndicate to develop an automated design optimization system for their yachts. Recognizing that the yacht design optimization problem had been poorly researched in the past, Andrew also enrolled in a Ph.D. by research on the

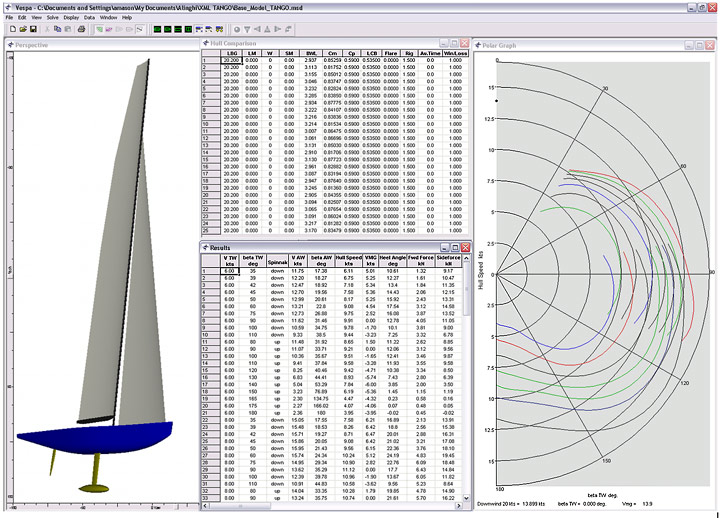

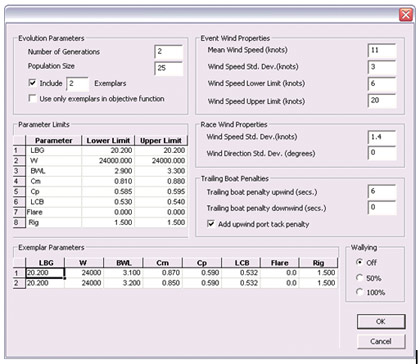

same topic, completing his dissertation in 2009. Read Andrew's design optimization thesis and other papers at his web site [site offline] During this period at Alinghi, Andrew developed and implemented VESPA (an acronym from Virtual Evolution-based Sailing Performance Analysis), a system specifically for the optimization of America’s Cup yachts. Using a Genetic Algorithm for optimization, coupled with neural-network-based metamodels derived from CFD analysis of different hull shapes, VESPA allowed meaningful improvements to be made to hull designs without requiring the use of supercomputer hardware. Virtual fleets of dozens of potential yacht designs were created and raced against each other throughout the simulation of a complete America's Cup cycle, and then the DNA of the highest-ranked hulls became the basis of a successive generation of candidate yachts for another round of analysis, allowing the many competing variables involved to be optimized for the best balance of the interrelated and sometimes mutually-exclusive race yacht characteristics. VESPA's power made it possible to blanket the design space of the ACC Class Rule, and then rapidly zero in on the most ideal hulls for the expected conditions. Please explain about your background with computers and yacht design? I wrote the Maxsurf hull design program and its accompanying analysis software (Hydromax, HullSpeed and the SPAN Velocity Prediction Program), commencing in 1984, and this was quickly adopted by a large number of yacht designers worldwide. After developing Maxsurf my interest turned to ways of automating the design process itself. It struck me that while Maxsurf made hull design significantly faster and easier than using a drawing board and doing calculations by hand, the process was essentially still a manual one, involving a lot of intuition and trial and error on the part of the designer. The technology of yacht design has advanced considerably in the past decade, with CFD codes becoming more accurate and computer hardware increasing in power. Yet many designers use CFD tools simply to assist with a “blind search” method -- analyse a design, look at the output and try to guess which direction to go next. What was required was a way of automating the design process, getting the computer to vary designs and search for the best possible outcome. This resulted in my researching optimization methods and putting considerable thought into how racing yachts, particularly America’s Cup Class yachts, could have their designs optimized without manual intervention. In particular, I concluded that the best optimization method for this particular problem was a Genetic Algorithm, a method that simulates the process of evolution in a biological species.

How does an evolutionary algorithm for design optimization actually work? An optimization algorithm simply searches a design space in an ordered fashion, attempting to improve on previous designs. In this sense it may be better to refer to the process as “automated design search”, as the term optimization tends to imply that you already have a very good design to start with that just needs a little bit of improvement. This is not the case, the algorithm should be able to start with a completely unrefined design and rapidly determine the best set of design variable values for the conditions specified. Biological evolution is actually an optimization process, where species are constantly adapted to the variations in their environment through the process of survival of the fittest. In the case of the America’s Cup, an evolutionary process also occurs. For the ACC boats, a new generation of designs was created for each cup cycle. These designs were based on the best ideas and best features from the previous cycle, with the design features of the least successful boats tending to die out. This cross-pollination of design ideas between the various teams, based on the results of the previous event, is very much like the processes of natural selection and sexual reproduction between the fittest surviving individuals in an animal population. So the America’s Cup results in true design evolution, combining competition between individuals, selection of successful designs as parents for the following generation, and crossover or cross-pollination of those design ideas from one designer to another.

This evolution of yacht designs in the real world can be considered to be an evolutionary algorithm, a sequence of steps that results in evolutionary improvement. Automating this process within the computer is simply a matter of simulating the performance of each design in a generation, then simulating a round robin tournament of races between each boat in the population, across a realistic distribution of wind conditions. At the end of each round robin, the win/loss ratio of each design is calculated and each design is ranked. The most successful designs are then used as parents for the next generation of designs and the least successful designs are eliminated. The result is that good design features are perpetuated, bad design features are eliminated, and the overall fitness of the population improves over time. When looking at the best way to optimize the design of ACC yachts using computer software, many different optimization approaches were available. However, the adoption of an evolutionary algorithm (more specifically, a Genetic Algorithm) was a natural choice due to the similarity with the actual process of design evolution within the America’s Cup competition. The work you have done so far modeling candidate designs under VESPA seems to have focused on the hulls, without considering variations in appendages. In a class with a narrow design space like the ACC version 5, appendages can be critical, but even with the full-sized boats in real world testing it can be hard to determine the best option. ETNZ in 2007 had two entirely different bulbs, one long and skinny and one more conventional. BMW Oracle on the other hand had two relatively similar keel and bulb combinations, but by some accounts chose the wrong one for the Louis Vuitton Cup semifinal and were eliminated. Should the appendages be considered in interaction with the hulls in a genetically-based design optimization, or are various keel and rudder combinations more or less independent of the hulls when it comes to their performance contributions? Keel and bulbs do interact with hulls, so late stage CFD testing and optimization should be done in conjunction with a hull model. The issue with the long bulbs in 2007 was that the longer bulb had higher wetted surface area but lower centre of gravity, so the choice of optimum was a trade-off between the two. This resulted in a fairly “soft” optimum which was not easy to determine. Keels and bulbs should have been an ideal topic for optimization within VESPA for AC32, but we simply did not have the time to get onto this. If AC33 had been held in the AC33 or AC90 classes, automated optimization of fin and bulb would have been a major target area for investigation. Some portion of the VESPA program extended existing methods into even more elaborate analysis, such as simulation of an individual race expanding into simulating the whole regatta using the expected weather conditions over time, but the most fundamental innovation seems like it was creating the code for the DNA of a very technical yacht class. How hard is it to build a workable genetic model for the shape of the ACC hulls, or even a similar Class Rule?

The key issue here is the set of transformations chosen to modify the geometry of the hull. The ACC v5 boats were complex in that they had fore and aft girths which could not be exceeded, and the length parameter measured, LBG, was taken 200mm above the DWL rather than at the DWL. Coupled with this was a requirement that the hull should not have concavities, and that the aft run should be straight rather than convex or concave, so there were significant constraints on what hull shapes were acceptable. Coming up with an effective way of automatically modifying hull shapes to meet specific dimensions and hydrostatic values, while meeting all of the constraints required by the ACC v5 rule, was a major challenge. For the AC90 and AC33 classes, the transformations had fewer constraints, but new parameters were required in that the transom width at the sheerline and turn of bilge (or chine) needed to be controlled independently of the beam and flare at midships. The degree of transom immersion also needed to be controlled independent of draft.

Can the Genetic Algorithms be adapted to the new AC72 multihull Class for the 2013 America's Cup? The Genetic Algorithm approach can be easily adapted to AC72 hull shapes, as the set of transformation control parameters I developed for the AC90 class is equally applicable to multihull forms. What is even more exciting is the prospect of uncovering significant gains through evolutionary optimization of both the wing rigs and lifting foils. What computing power did you have available? For the VESPA work we utilized a 32-CPU cluster running the SPLASH potential flow code to perform the CFD analysis runs. This took four to five days to calculate about 250 data points for each of 25 design variations. Fitting of neural network metamodels to this data then took about three days on two dual-core PCs. VESPA itself then ran very efficiently, a complete optimization run would go overnight (12 hours) on a 1.6 Ghz single-core laptop. What might be possible if you had access to the latest supercomputers, or the next generation?

Computer power for CFD is never sufficient, it could increase by several orders of magnitude and we would still manage to slow it down with ever more sophisticated CFD models. The key is using the computer power intelligently to extract the most information out of a small number of analysis runs and to accurately approximate the solution between the data points analysed. This is where the concept of surrogate models (or metamodels) comes in. Most people are familiar with the concepts of statistical regression, doing a linear, quadratic, or cubic least-squares fit to scattered data. Metamodels use significantly more powerful fitting methods to accurately approximate complex, non-linear data in a large number of dimensions. Probably the best of these methods is the Radial Basis Function Network, and these have several advantages over the standard Artificial Neural Networks used within VESPA in 2007. The vendors of commercial CFD codes such as Fluent and CFX prefer to licence their software per CPU core, so the greater the number of cores the more expensive the run. And commercial supercomputer centres also wish to charge by the number of CPU cores utilized. As a result, things get very expensive very quickly, and while the large teams will be able to negotiate heavily discounted rates, the total cost of the CFD work can be very high. As I see it, the next big advance in CFD will come through the use of free, open-source CFD software such as OpenFOAM, coupled with hardware based on highly parallel GPU units such as the nVidia Tesla graphics cards. I’m not normally a fan of open-source software, but OpenFOAM is an exception. The Tesla cards are an untapped resource at the moment. They are very low cost but contain hundreds of cores, for example I could put together a desktop machine that contained over 1000 cores for only a few thousand dollars. Such a hardware and software combination has the potential to dramatically reduce the cost of CFD analysis, allowing teams with limited budgets to do substantially more analysis runs. If one of the teams is prepared to do some early R&D to get an appropriate solver running on nVidia GPU hardware, they have the potential to reap significant benefits downstream, as the hardware and software is highly scalable at minimal cost. Unfortunately, America's Cup teams are usually set up as three-year or four-year projects with no guaranteed life beyond that. As a result, most teams are actually quite averse to spending money on tool development and prefer to use off-the-shelf design and analysis software Alinghi was an exception to this rule, viewing development of new technology as intellectual property that adds to the long term success of the team. In particular, without the long-term vision of Grant Simmer and the willingness of Ernesto Bertarelli to fund the work, VESPA would not exist today. How did VESPA affect the design outcome of the 2007 AC? VESPA always had to compete with the conventional design development work carried out by Rolf Vrolijk, quite a formidable task. But one of the early successes was finding a hull configuration that was superior to SUI-91 across the whole wind range, both upwind and down. What we found was that VESPA consistently favoured boats with a boxier mid-section and less beam than Rolf’s boats.

VESPA also provided some insights into the effects of different design variables. A good example is the presence of topside flare. It has been said that the problem with sailing conditions in Auckland was that while the average wind strength was 15 knots, it was because 50% of the time it blew 5 knots and 50% of the time it blew 25 knots. This may have been an exaggeration, but Auckland does have a large variance in day-to-day wind strength. By comparison, Valencia has a similar mean wind strength but much lower variance, as it has a reliable sea breeze which can be almost the same for many days in a row. VESPA showed that when an event was held in a location where there was a large day-to-day variation in wind strength, flared topsides and a narrower waterline beam could be a competitive configuration, whereas for a venue with low variance, such as Valencia, vertical topsides were favoured. This allowed the Alinghi design team to eliminate flared topsides as an option fairly early. This was interpreted as being because a hull with narrower waterlines and some topside flare would have improved performance in light winds and on downwind legs, but could recover a bit of stability on the upwind legs due to the flare used. With the comparison of Alinghi's designs to those of ETNZ, we had very good estimates of the key parameter values of their boats. I was able to include boats having these design characteristics in the VESPA population to see what effect they had on the determination of the optimal design. The key finding was that if NZL-92 was assumed to be the opponent, it was always advantageous for Alinghi to have a boat that was slightly wider with slightly better upwind performance, even at the cost of a small amount of downwind speed. VESPA gave the Alinghi team a lot of confidence that SUI-100 was a superior boat to NZL-92. Although VESPA indicated that SUI-100 may have

been even faster if it had been slightly narrower and boxier in the mid-section, we ran out of time to tank test such a model, so this prediction by VESPA could

not be validated.

In the initial phase of AC33 I focused on adapting VESPA to the AC90 and the AC33 class. However, once Alinghi lost the first court case and was forced to focus on multihull design, it became apparent that the time available for the A5 design cycle (only a few months) was insufficient for a formal optimization project. More importantly, an optimization project would have sucked up people and resources, so it was clearly not appropriate for such an urgent timeframe. If Alinghi had been given the luxury of more design time, VESPA could have been reconfigured easily to handle multihulls and the outcome might have been different. But that is the nature of the America’s Cup, time lost at the start of a design cycle cannot be made up later. Have you considered investigating historical America’s Cup classes and venues using VESPA? For example, given the large population of 12-meter boats, and the many years they raced at Newport, would it be of interest to find which were optimal for the event? And maybe how the ranking differs when shifted to Fremantle?

I haven’t considered it, since setting up a design optimization is quite a time consuming and expensive process. But the genesis for my work came from design optimization work done by the Stars&Stripes team for the 1987 Cup. This was truly ground-breaking work, being the first to apply Monte Carlo tournament simulations and game theory to the problem, and its importance is greatly underestimated by many of today’s generation of America's Cup designers. The resulting boat, a heavy-air flyer that had to be desperately reconfigured and remoded in order to avoid elimination in the light-air, early rounds of the challenger selection series, was the perfect design for Fremantle in January 1987. But for just about any other venue and wind strength distribution, Stars&Stripes '87 was a poor performer. If two candidate boats are close in their relative performance, they will engage in more tacking or gybing duels, and may need to change gears and out-point each other at critical moments. Can or should human or tactical factors be modeled? For AC32 the v5 rule made it easy. Length, displacement, and sail area were effectively the same for all boats, so their performance tacking and gybing could be assumed to be similar for all designs and we could ignore the effects of manoeuvring on performance. The goal with VESPA was to locate the fastest design for a given wind distribution, not to be concerned with how that boat was then used by the sailors. The method produces an inherently robust design that is capable of performing in a range of expected conditions and sailing angles, not just one particular wind strength and pointing angle.

The hard wing sail has been described by designers as easier to analyse a given wing shape using CFD because the foil shape is a fixed surface, unlike the surface of a soft sail which is shaped by the airflow passing over it. How does the genetic metamodeling of a wing sail lend itself to being adapted for analysis similar to what VESPA did for the ACC hulls? The use of metamodels and genetic algorithms for design search and optimization has been widely used in the aerospace industry for wing planform design, aerofoil profile design, and the design of high-lift, multi-element aerofoils. So the methodology is directly applicable to the design of wings for the AC72. The difference is that aerospace designers are not necessarily familiar with having to design for wind gradient and how it results in variations in angles of attack at different spanwise locations, nor are they familiar with the use of a VPP linked to a probabilistic tournament model to determine the measure of merit for a particular wing design. A Genetic Algorithm is also an ideal way of exploring different flap geometries and settings and their effect on performance around a racetrack in a variety of conditions. Is it within reach to model the wing and the hull shapes parametrically and test them simultaneously via a genetic analysis? Similar to underwater appendages, can they be adequately tested independently?

While a wing may be able to be simulated and optimized to some extent in the absence of a hull model, the final optimization needs to be performed using a VPP which combines the aerodynamic and hydrodynamic models. Underwater appendages, particularly lifting C or J foils, definitely need to be optimized in conjunction with the hull design as they can significantly change the trim of the vessel and therefore the optimal design for the hull. There has been recent discussion in the design community that CFD is maturing to the degree it will completely replace tank testing, if not in the coming America's Cup, then probably in the following one. I don’t think this viewpoint is correct. While tank testing has largely ceased being used for design exploration, with CFD taking over that role, the tank remains essential to provide validation and verification of the CFD results. I think it will be a long time before CFD is considered sufficiently accurate that an America's Cup team will be willing to build a boat based solely on the CFD results, without verification of the design in the tank.

Without hard data on the AC72’s real world performance, especially considering that it is still a year before the boats will even be launched, is there enough resolution in the performance models to apply VESPA’s methods yet? Where would a newly formed AC34 design team start? The quality of the CFD software available is adequate for calculation of hulls and wings. In many ways the problem is simpler than it was for analysis of the ACC v5 yachts, due to the slenderness of the catamaran hulls and the rigidity of the wings. The starting point for any team is with experienced hull and wing designers, backed up by good CFD people. Being able to set up a reasonable base design is the first step in any design optimization process, regardless of whether that process is automated or a manual procedure. Are existing Velocity Prediction Programs (VPP) up to the task of designing and analyzing large multi-hull racing yachts like the AC72 in a match-race setting? A VPP is simply a program that finds equilibrium between aerodynamic and hydrodynamic forces. What counts is the quality and accuracy of the hydrodynamic and aerodynamic force models used by the VPP. These can be derived from CFD results, or tank and wind tunnel data for a specific design, or alternatively from a global metamodel derived from CFD data for a large number of design variations. There are issues to do with verifying and validating that the CFD software is giving accurate results for the particular types of hull, rig and appendages, but once that is done the VPP should provide good answers. What is your opinion of the advantage some people perceive that BMW Oracle has in multihulls and particularly in wingsail design? Is this advantage insurmountable for a challenging team?

Actually, I think this purported advantage is a myth. The wing used on the BMW Oracle trimaran was aerodynamically simplistic, and if scaled down to the correct size for an AC72, would not be competitive with the first generation of AC72 wings that we will see in 18 months time. The wing was simple for good reason, it was a gargantuan task to get it built and sailing in the time available, and it needed to work straight out of the box and be robust and reliable. In that respect the BMW Oracle design team did a fantastic job, if they had gone for a more complex design, chances are that the wing would have been too late or too unreliable. The team picked the correct level of design complexity for the task at hand, which was simply to be faster than Alinghi, not to produce the fastest possible wing design. This time around it will be different, and aerodynamically BMWO will have to start from scratch with all the other teams. The wings will be very different, possibly with all elements able to twist and the likelihood of more than two elements being used. I would also not count on the C-Class cat rigs being a model for what we may see in AC34. While the C-Class designers have done a fantastic job developing the rigs to where they are, they have had to work with little or no CFD facilities, relatively small budgets, and small sailing crew numbers, so the wing designs have been fairly simple as a result. It will be interesting to see what features prevail in the design of the AC72 wings in an environment of high budgets, extensive CFD, and large crew sizes. Although I think that aerodynamically and hydrodynamically BMWO does not have any real advantage over a good challenging team, I do concede that BMWO has a significant advantage in the structural design of the wing and platform. The combination of the load data collected from sailing the trimaran with the knowledge and experience of former Alinghi structural designer Dirk Kramers will be difficult to match. Combine this with the experience of the BMWO build team and it will be hard for other teams to match the structural integrity and quality of the BMWO boats. Why aren't more teams using automated design optimization methods in their work?

There is a perception among the public that the America's Cup design world uses cutting-edge analysis methods based on significant R&D investment. Nothing could be further from the truth. Most teams use off-the-shelf commercial CFD and FEA software, and there is little time or budget available to investigate or develop new design and analysis technologies. This tends to result in many teams being blinkered in their evaluation and adoption of new technology. Rather than doing a proper literature search and evaluation of alternatives, they often adopt a “not invented here” mentality and choose methods with which they are already familiar. The field of optimization has made significant advances in the past 10 years, particularly in the areas of evolutionary algorithms and the use of metamodels. Unfortunately, most America’s Cup design team personnel remain unaware of these developments, and do not have exposure to modern optimization methods. As a result, optimization tends to be neglected, or rejected outright on the basis that it is believed to be:

In fact, none of the above statements is true. Meaningful optimization is possible within a reasonable budget, on relatively low cost computers, within reasonable time-spans. More importantly, the experience with VESPA in 2007 showed that automated optimization can make significant improvements to the best designs generated by experienced yacht designers. With the adoption of winged catamarans for AC34, the benefits of using optimization methods to explore the design space are overwhelming. In 2007 we were trying to eke out small gains to highly refined designs which had resulted from more than 15 years of development in the class. This time around the design space is largely unexplored for hulls, wings, and foils, and I have no doubt that some major breakthroughs await those teams that embrace the use of advanced optimization methods. Thanks Andrew!

Additional Links and Info: White Papers and research by Andrew Mason explaining his creation and use of VESPA: The easier starting point is the paper titled "Stochastic Optimization of IACC Yachts" (20 pages total, pdf). More extensive is Andrew's full

Ph.D. dissertation, "Stochastic Optimization of America's Cup Class Yachts" (226 pages total, pdf). The short paper gives a more direct overview, but even

though the full dissertation goes into great depth, it also has more space to define terms and explain concepts. See his website Optimar [no longer

online]

Jan 11, 2010, 6:00 am PT |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||