A Look Inside Emirates Team New Zealand's

Portsmouth Base

Kiwis Prepare for Racing, Feeding Mind, Body, and Boat

|

Friday July 24, 2015 |

Outside it's a dreary day in Portsmouth, a good time to get out of the rain

before the practice races and go inside the white tent at right, paying a visit

to Emirates Team New Zealand.

Photo:©2015 R. Steven Tsuchiya

Ambassadresses of team sponsor Emirates Airlines distract observers from the

down to earth work that goes on to keep sailors in winning form.

Photo:©2015 R. Steven Tsuchiya

Sean Regan, Emirates Team New Zealand boatbuilder, unspools a length of

carbon fiber fabric which can be used to repair small areas of damage on the

boat. White material on right is

used in applying graphics.

Photo:©2015 R. Steven Tsuchiya

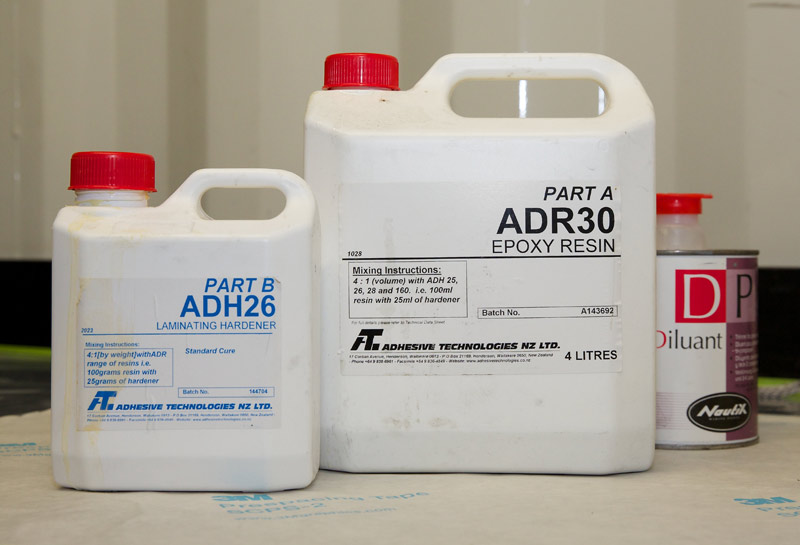

Regan mixes a batch of epoxy, which will be soaked into the carbon fiber

fabric applied in the repair.

Photo:©2015 R. Steven Tsuchiya

Recipe for a quick patch: ADR 30 is an epoxy resin that cures quickly at room

temperature. ADH 26 is a relatively fast acting hardener for ADR which likewise does

not require elevated temps.

Photo:©2015 R. Steven

Tsuchiya

In addition to wearing well, Durepox paint serves as an effective moisture seal

over carbon fiber. The product was widely used on the America's Cup Class

monohulls as well. In satin finish the paint offers low surface resistance

characteristics without violating rules regarding the flow of water within the

boundary layer.

Photo:©2015 R. Steven Tsuchiya

Uniforms in new design debuted in Portsmouth.

Photo:©2015 R. Steven Tsuchiya

Pre-race briefing. Glenn Ashby standing, at center.

Photo:©2015 R. Steven Tsuchiya

Recipe for Lunch: Sailors need to eat before they race, too, but this fare is

intended for VIP guests.

Photo:©2015 R. Steven Tsuchiya

On a sunny day, ETNZ shore crew rolls the AC45F out of the tent to prepare for

stepping the wing mast, visible inside at left. Photo:©2015 R. Steven Tsuchiya